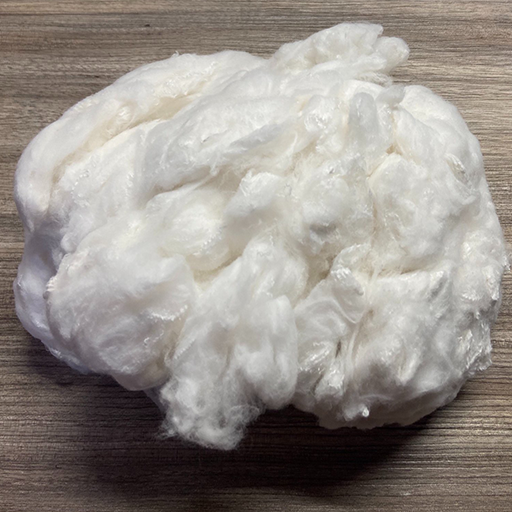

PVA Fibre (Polyvinyl Alcohol Fibre) — 1.2D & 1.5D Grades

Product Overview:

PVA fibre is a water-soluble synthetic fibre widely used across textile, packaging, and non-woven industries. It offers tailored solubility and high-performance compatibility for various blending and processing applications.Natural Color

1.2 Denier (D)

1.5 Denier (D)

These fine denier fibres provide excellent dispersion, uniformity, and compatibility with both natural and synthetic fibres.Dissolution Temperature Grades (°C):

PVA fibre is available with controlled solubility at the following temperature thresholds:40°C

50°C

60°C

70°C

80°C

90°C

This range allows for precise selection based on process requirements, making it ideal for applications involving:Yarn core removal

Fabric structuring and shaping

Controlled disintegration during dyeing and finishing

Temporary support in high-performance or specialty textiles

Key Advantages:

High tensile strength and excellent elongation

Biodegradable and environmentally friendly

Customizable dissolution profiles for diverse industrial uses

Main Applications of PVA (Polyvinyl Alcohol) Fibre

The best mechanical double cottonised we make is the HONEY type which is used in linen rich blends upto 55% linen with long staple cottons in finer counts.

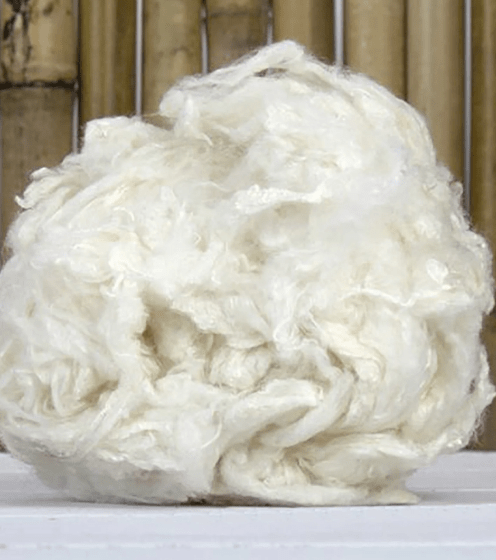

Bleached Linen Fibre – Belgium origin

1. Water-Soluble Non-Woven Fabric Production

PVA fibre is a key raw material for producing water-soluble non-woven fabrics, which are commonly used as:Embroidery base cloths

Machinery-made lace with a handcrafted appearance

Disposable industrial textiles, meeting the stringent hygiene and sanitation requirements of specialized industries

2. Water-Soluble Fine-Spinning Yarn

Used in the production of water-soluble yarns that, when woven with other fibres, can be dissolved during dyeing and finishing processes to create:Jacquard-style openwork fabrics

Warp and weft hollow-out structures

Lightweight, soft, and voluminous textiles

Delicate lace and decorative textiles

3. Intermediate Fibre for High-End Wool Textiles

PVA can be interwoven with low-count wool (or top) to aid spinning. Once removed during dyeing and finishing, it helps achieve:High-count, lightweight, and soft pure wool fabrics

Bulky and high-grade textures

Improved yarn strength for enhanced spinning performance and expanded design versatility

4. Blending with Cotton, Hemp, and Polyester

PVA fibre can be used as a sacrificial component when blended with:Cotton to produce high-count pure cotton fabrics

Hemp for lightweight, soft, pure hemp textiles

Polyester to replicate silk-like textures in synthetic fabrics

5. Enhancing Pashmina and Low-Strength Fibres

When interwoven with fibres like pashmina, PVA:Improves spin-ability and yarn formation

Acts as a supportive scaffold, then dissolves during processing

Enhances final product quality without leaving residues

6. High-Count Water-Soluble Yarn Blends

PVA fibres blended with cotton can be used to produce:High-count water-soluble yarns, ideal for advanced textile applications where temporary structural integrity is required during fabrication