100% linen Fiber

Linen fibre is plant fibre collected from the phloem (the "inner bark" or the skin) or bast surrounding the stem of certain, mainly dicotyledonic, plants. They support the conductive cells of the phloem and provide strength to the stem. Most of the technically important bast fibres are obtained from herbs cultivated in agriculture, as for instance flax, hemp, or ramie, but also bast fibres from wild plants, as stinging nettle, and trees such as the Tilia, have been used to some extent. Since the valuable fibres are located in the phloem, they must often be separated from the xylem material ("woody core"), and sometimes also from epidermis. The process for this is called retting, and can be performed by micro-oganisms either on land (nowadays the most important) or in water, or by chemicals (for instance high pH and chelating agents) or by pectinolytic enzymes. In the phloem bast fibres occur in bundles that are glued together by pectin and calcium ions. More intense retting separates the fibre bundles into elementary fibres, that can be several centimetres long. Often bast fibres have higher tensile strength than other kinds, and are used in high-quality textiles (sometimes in blends with cotton or synthetic fibres), ropes, yarn, paper, composite materials and burlap. A special property of bast fibres is that they contain a special structure, the fibre no

Hemp

Hemp is biodegradable and eco-friendly fiber with highest tenacity in natural fiber. Hemp fiber contains phenolic substance , so it has anti-mouldy and bacteriostatic property, bacteriostatic effect is quite obvious for Staphylococcus aureus, Pseudomonas aeruginosa, Escherichia coli, Candida albicans.

Linen / Flax Fibre Specifications

Flax Fibra – Belgium Origin

Natural Color

Type Moon Dark (Natural)

Suitable for blends upto Ne 12 without problems in 70/30 and even higher linen content. Popular fiber for Standard yarns in coarser counts with viscose, cotton or polyester and slub effects to be used in upholstery fabrics. Many yarns can be developed on request of local customers.

Type MOON (Natural) best seller for mass production of weaving yarns for shirting and pants Used a lot in cotton/linen Blends

There are indeed several markets (yarn types) to work on:

Standard yarns in Ne 12-16 and 20 with 65-35 cotton/flax content are an old South Indian standard which is used by local weavers to make a shirting fabric in Ne 20 and pants in Ne 12

There is the market of the finer counts in weaving yarn : Ne 28-30 with linen content between 20 to 30% where they use the yarn in weaving but know mainly in knitting which is coming up strongly.

For this type of yarns we mainly sell the LAURA or the even shorter JULIE

The best mechanical double cottonised we make is the HONEY type which is used in linen rich blends upto 55% linen with long staple cottons in finer counts.

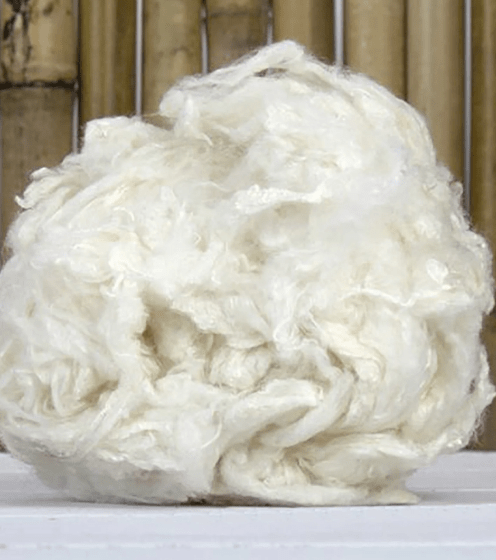

Bleached Linen Fibre – Belgium origin

The SNOW type is most famous in blends with polyester or cotton for melange yarn production it is moon that we bleached and reopened and passed on cotton cards.

Linen / Hemp Yarn Data

100% Linen Yarn

Lea 16, 24, 36, 44 & 60.

LINEN BLENDED YARN :

Ne 10s to Ne 40s